THREE-DIMENSIONAL MESOSTRUCTURES AS HIGH-TEMPERATURE GROWTH TEMPLATES, ELECTRONIC CELLULAR SCAFFOLDS, AND SELF-PROPELLED MICROROBOTS

Zheng Yana,b,1, Mengdi Hanc,d,e,1, Yan Shif,g,h,i, Adina Badeaj , Yiyuan Yangk , Ashish Kulkarnic,d, Erik Hansonl , Mikhail E. Kandelm, Xiewen Wenn , Fan Zhangf,g,h, Yiyue Luoc,d, Qing Linc,d, Hang Zhangf,g,h, Xiaogang Guof,g,h, Yuming Huangc,d, Kewang Nano , Shuai Jian , Aaron W. Orahamj , Molly B. Mevisj , Jaeman Limc,d, Xuelin Guoc,d, Mingye Gaoc,d, Woomi Ryuc,d, Ki Jun Yup , Bruno G. Nicolauj , Aaron Petronicoj , Stanislav S. Rubakhinj , Jun Loun , Pulickel M. Ajayann , Katsuyo Thorntonl , Gabriel Popescum, Daining Fangq,r, Jonathan V. Sweedlerj , Paul V. Braunc,d, Haixia Zhange , Ralph G. Nuzzoc,d,j, Yonggang Huangk,s,t, Yihui Zhangf,g,h,2, and John A. Rogersk,t,u,v,w,x,y,2

PNAS, 114 (45) Pages E9455-E9464 2017

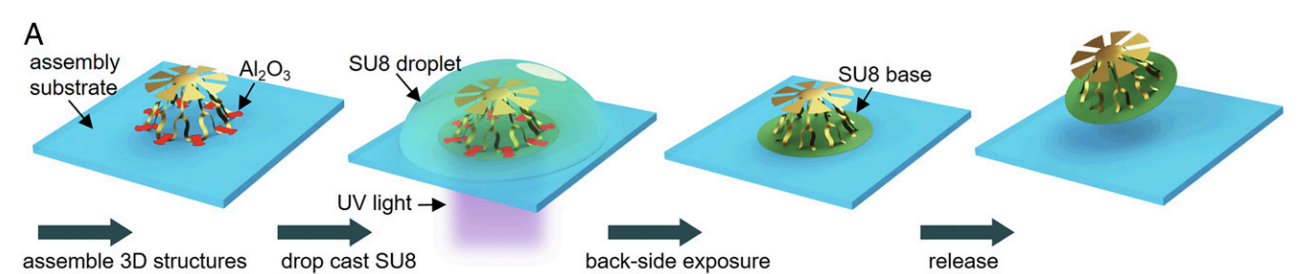

![]()

Recent work demonstrates that processes of stress release in prestrained elastomeric substrates can guide the assembly of sophisticated 3D micro/nanostructures in advanced materials. Reported application examples include soft electronic components, tunable electromagnetic and optical devices, vibrational metrology platforms, and other unusual technologies, each enabled by uniquely engineered 3D architectures. A significant disadvantage of these systems is that the elastomeric substrates, while essential to the assembly process, can impose significant engineering constraints in terms of operating temperatures and levels of dimensional stability; they also prevent the realization of 3D structures in freestanding forms. Here, we introduce concepts in interfacial photopolymerization, nonlinear mechanics, and physical transfer that bypass these limitations. The results enable 3D mesostructures in fully or partially freestanding forms, with additional capabilities in integration onto nearly any class of substrate, from planar, hard inorganic materials to textured, soft biological tissues, all via mechanisms quantitatively described by theoretical modeling. Illustrations of these ideas include their use in 3D structures as frameworks for templated growth of organized lamellae from AgCl–KCl eutectics and of atomic layers of WSe2 from vapor-phase precursors, as open-architecture electronic scaffolds for formation of dorsal root ganglion (DRG) neural networks, and as catalyst supports for propulsive systems in 3D microswimmers with geometrically controlled dynamics. Taken together, these methodologies establish a set of enabling options in 3D micro/nanomanufacturing that lie outside of the scope of existing alternatives.